DATE: 10th June, 1986

TALK BY: Dr. Michel David

Re: ERRORS THAT CAN BE AVOIDED IN RESERVE ESTIMATION

This talk was not an expose of the geostatistical ore reserve technique but rather a philosophical discourse on the nature of misconceptions which occur in ore reserve calculation procedures and their relative significance. A number of points of interest were made and these are briefly given here not only as a matter of record but to inform staff of these basic misconceptions and ways of

assessing the significance of assay data. I guess many of the points are obvious but bear thinking about.

Geostatistical

(or any other technique for that matter) ore reserve estimation requires some

training, but recognising calculations based on faulty principals or wishful

thinking takes only a few minutes to learn and three basic principals only

should be accepted. These are given later.

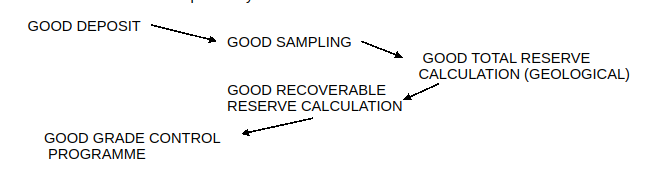

For successful development and mining of an ore body the ore reserve estimation must be reliable and progressive based on good sampling and calculation techniques, the

“flow” of reserve estimation over the life of a deposit may be summarised as follows:

Inherent in the discovery of a good deposit based on a successful drilling programme is the “psychological bias” i.e. “successful drilling tends to bias reserve estimates towards higher tonnages and grade” and a corollary of this that “ore reserve estimation is not simply a matter of converting various intersection lengths and assays to tonnage and grade whether by hand or delegating the task to a black box”, (after Haddon King).

The basic principles, which should be addressed, are:

1) SAMPLE VALUE

DETERMINED BY A LABORATORY IS NOT THE GRADE OF THE CORE BUT THE VALUE OF THE

SAMPLE ASSAYED.

For example, a

20gm sample weight split from 20kgm of crushed and pulverised core is highly

likely to have a different value to a sample of weight 50gm or 500gm etc.

especially for say gold or similar low content element. Similarly, different

assay values from different crushed splits or repeat assays by different

laboratories of the same core interval may all be valid and correct for the

actual assayed samples, the differences reflecting original distribution of

material in core or how a limited number of grains have distributed themselves

in the pulps prepared for assay. None are necessarily wrong, (or right!).

Probably average of all values is closer to the true value.

2) GRADE OF CORE

IS NOT GRADE OF STOPE OR ASSAY BLOCK FROM WHICH THE CORE WAS EXTRACTED.

Relevance of core

is often over rated. In fact it can be said a given length of core does not

represent that block of ground it came from ie that

particular bit of rock is no longer in the ground, and it is the value of that

which is left to be mined that is important not what is sitting in the core

shed. Again this is more important for precious metals than say a volcanogenic

sulphide deposit, for example what value do you place on say a 200g/t Au assay

value in a section of core in a given drill hole when a nearby drill hole

assays 0.2g/t ie does the 200g/t assay value reflect

a single small grain fortuitously picked up in the assayed sample split or does

the 0.2g/t value mean that the cored interval just missed a large 200g/t but

irregularly mineralised zone etc.

An example of how

core assay variability influences reserve estimation is, taken from a gold mine

in

|

|

|

|

Both metre-gram

(m-g) values are similar but in terms of mining and assessing a

mineable reserve which is most valid to use eg. taking mining cost into consideration, is it better to base

reserve on the 9 metre intersection or 12m intersection value? It may not be economically viable to mine the

12m section because of the necessarily larger plant size requirements etc. to

cater for larger reserve etc.

3) GRADE IS NOT

RANDOMLY DISTRIBUTED

This is a basic

tenet of geostatistical ore reserve estimation in that the assumption is made,

supported by empirical and actual observation, that there are systematic and

statistically quantifiable changes in the distribution of any mineralisation,

for example, high grade zones are surrounded by lower grade zones etc., or a

high grade block is likely to be surrounded by lower grade blocks.

The grade

variation may be “ordered” by means of a variogram plot, which is a

function of the sample interval, and serves to smooth and determine rate of

variability. For example, “waste” may only be waste because a

particular drill hole in a given block is low, but it may in fact be ore i.e.

too much reliance on a given bit of core or blast hole assay value and not

attributing enough weighting to ore distribution trends and variation through

the ore body. That is, a “low”

zone surrounded by ore is more likely to be a “low assay” from the

ore zone and not barren rock, unless there is a particular geological reason

why a given site should be low or barren.

Within a

mineralised zone the use of the variogram to determine grade has the affect of

increasing lower grade values and decreasing the higher-grade values i.e.

values trend towards the average. This is observed in practice during mining

i.e. the recovered grades in lower grade sections tend to be higher than

anticipated from drilling and lower in higher grade sections.

|

|||||

![]() real

real

![]() recovered

recovered

![]() grade

grade

estimated

value

Choice of sample

is important to get good statistics because grade of sample used is not

necessarily representative of the block from which it came. This is a reflection of numbers of grain

particles assayed, for example would need 20 gold particles/assay sample (10gm)

to get a 20% precision; (about 10,000 particles to give 1% precision), often a

highly unlikely occurrence.

As an example,

best grade control technique at an open pit Au mine in

reduces bulk of sample considerably but retains the total number of gold

particles. In this

both large sample size and increased numbers of particles being assayed

contributed positively to good grade control.

From elsewhere

Professor Krige has discussed the problem of defining

the degree of uncertainty in grade estimates based on borehole data from new

discoveries. He states that even if the property does not form the extension of

an existing ore-field, as for example in the

linked to similar deposits elsewhere. In such a case, a grade estimate that

falls outside the range encountered in the other deposits should always be

queried, no matter how sophisticated and statistically efficient the

computational method employed.